Introducing the Kemppi AX MIG welding machine. The robotic unit is built for high-intensity, 24/7 automated welding environments. With 400- or 500-amp power and a robotic wire feeder, it is designed to perform difficult tasks and meet demanding production targets, the company states.

The unit’s precise seam tracking signal helps ensure repeatable, quality welds. For challenging materials, the manufacturer’s Max or Wise arc performance welding processes can be used to help increase speed, lower heat input, and ensure penetration. Material Handling Robots

The WELDER, formerly known as Practical Welding Today, is a showcase of the real people who make the products we use and work with every day. This magazine has served the welding community in North America well for more than 20 years.

Easily access valuable industry resources now with full access to the digital edition of The FABRICATOR.

Easily access valuable industry resources now with full access to the digital edition of The WELDER.

Easily access valuable industry resources now with full access to the digital edition of The Tube & Pipe Journal.

Easily access valuable industry resources now with full access to the digital edition of The Fabricator en Español.

Andy Billman joins The Fabricator Podcast to talk about his career in manufacturing, the idea behind Arise Industrial,...

© 2023 FMA Communications, Inc. All rights reserved.

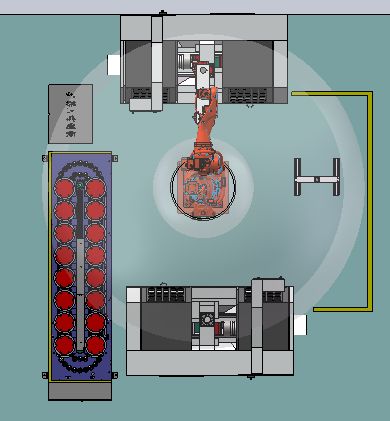

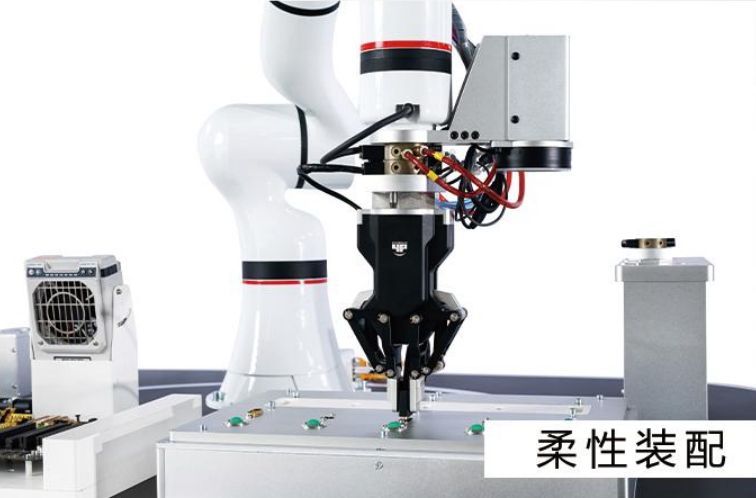

Collaborative Welding Robot Not yet registered? Sign up