The Megacoat Tough coating combines a wear-resistant layer on the surface adhered to high-content CBN, which provides greater fracture resistance when encountering interruptions.

Kyocera Precision Tools has introduced its KBN020 CBN grade to provide a larger range of hard turning capabilities. Milling And Drilling

Kyocera’s KBN020 is designed to perform in a broad application range, from continuous to interrupted machining. Kyocera recommends the grade for hardened materials (55 HRc or more), as well as external and internal turning, facing and boring.

Using new layering techniques, Kyocera has developed its Megacoat Tough coating technology. This coating combines a wear-resistant layer on the surface adhered to high-content CBN, which is used to toughen up the edge for greater fracture resistance when encountering interruptions. The adhesion layer is laminated between the wear-resistance layer and the CBN to reduce layer peeling for longer tool life and stable machining. Providing wear fracture resistance gives the user more flexibility, range, performance and tool life when turning hardened materials.

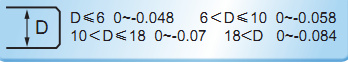

To take full advantage of Kyocera’s new hard turning technology, follow the listed speed and feed recommendations to optimize tool life and surface finish.

The ModuMiniTurn modular turning tool system provides exceptional repeating accuracy for the cutting point when swapping out modular heads for new inserts.

The TungThread indexable threading tool series is designed for applications including general parts that are machined in CNC lathes and small precision parts in Swiss-type automatic lathes.

Boring Cutter The company has developed two new tools to support Y-axis turning: CoroTurn Prime and the CoroPlex YT twin-tool.